Many leaders in the supply chain have often different expectations of what a control tower can do for their business and how it might help them. As a result of digitization, the control towers have turned from a labor-intensive solution to a fundamental system for the automated orchestration of supply chain orders.

In short, a giant leap was caused in the innovative and disruptive technology of the Control Tower – in the new, volatile environment, they are critical to success.

However, the question remains: what are the key challenges faced by companies that are driving the need for a digital control tower platform? That’s the topic of today’s blog entry.

Reason # 1 You need better end-to-end visibility of real-time events

Study # 1: Only 6% of 623 supply chain professionals in 17 countries believe that they have achieved supply chain visibility, according to a GEODIS survey. Interestingly, 70% of respondents currently describe their supply chain as very or extremely complex.

It is no secret that supply chains are becoming ever more complex. With the broadening of the range of products, personalized products (mass customization), order fluctuations and shorter delivery times, logistics operators are expected to capture, analyze and respond to a wider range of information faster than ever, with no flaws in the process. The pressure may be all too familiar to supply chain executives, as many of them are at a loss when it comes to improving their processes because of a general lack of awareness throughout their supply chain.

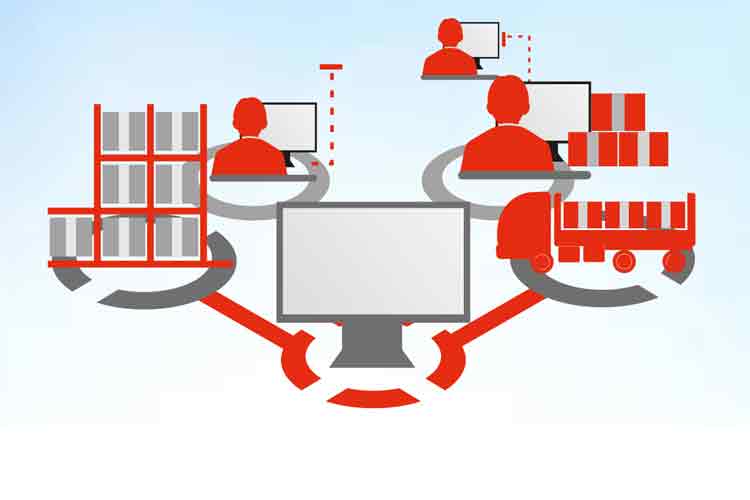

As complexity increases daily, digital control towers provide some sort of ‘’source of truth’’ about all jobs. They ensure real-time management of transports from events and across to all transport stakeholders, so you can really manage everything without exception, not having to worry about other things.

Reason # 2: You need to work better with external parties

Study # 2: When PricewaterhouseCoopers (PwC) interviewed 209 global companies as part of the “Global Supply Chain and Risk Management Survey“, 74% agreed that the number of companies in the supply chain had increased over the past three years. And it’s a growing problem: 94% of respondents said that changes in the extended supply chain network configuration are more common, and 95% agreed that the discrepancies between the supply chain instances have increased.

While end-to-end visibility is usually number one on the enterprise list when it comes to Control Tower, visibility and collaboration with its suppliers, partners, and other external parties are in second place. It is no longer possible to run the entire supply chain internally, which means that more external partners have a role that has a significant impact on the customer experience.

A Digital Control Tower focuses on building and executing the collaboration with internal and external partners and the systems used to orchestrate orders through appropriate partners for each order as well as in coordination with other assignments. This means more custom ordering, more on-time-in-full (OTIF) orders and more efficient ordering processes that save time and money – on all sides.

Reason # 3: You need more flexibility in your technology package

Study # 3: Is my current supply chain organization perceived as too complex? 89% say “yes”, 52% associate complexity with “slow decision-making speed and lack of flexibility” – Accenture, 2017.

Whether it’s adding new products with unique requirements, offering customers new service options, or serving markets they’ve never served before, which is a constant in the business, only the most agile companies can benefit. However, silo-like and rigid structures often limit the flexibility of the supply chain and the ability to meet the demands of the market.

Digital control towers connect and expand established structures. They provide configurability and flexibility in organizing and running the supply chain across multiple partners. They are designed to scale supply chain operations so that supply chain managers can respond flexibly to current and emerging business needs imposed on them by customers, regulators or competitors.

Digital Control Tower: It’s about action

Supply chain orchestration is only as good as the visibility, collaboration, and optimization that it responds to. The latter is the most important feature of digital control towers. As supply chains become more complex, and more and more requirements, events, stakeholders and regions need to be addressed, logistic experts need a digital platform to instantly streamline the execution of jobs across these variables. Digital control towers are built to orchestrate complex supply chains and provide customers with a perfect experience. Sooner or later, every customer order in the emerging experience economy (B2C and B2B) will require its own micro supply chain, which will be managed consistently and in real time: for perfect orders in 2018!