A disruption in the supply chain that occurs elsewhere in the world can have a significant impact on your consumers, your organization, and your supply chain as we all learned during the last 2 years. Natural disasters, global health pandemics, political unpredictability, economic upheaval, cyber and terrorist assaults, supplier threats, and fast swings in customer preferences and demand can all cause disruptions in supply chains. Because it is simultaneously ubiquitous and unexpected, supply chain disruption is no longer a question of “if” it will happen, nor is it actually a question of “when” it will happen.

You need to give an answer to the following question: Will we be able to prevent the next disruption in the global supply chain that comes our way?

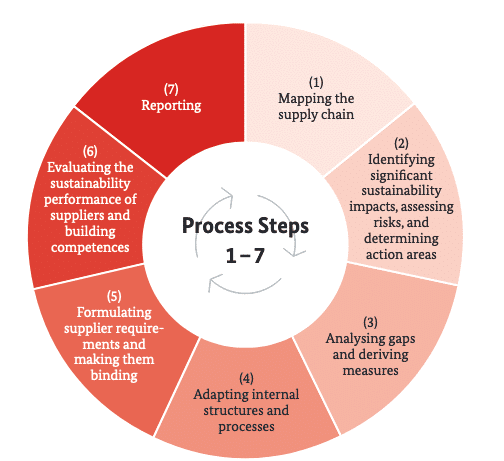

Mapping your supply chain

When the supply chain is mapped out and visualized, it is easier for the organization to get an overview of the critical upstream operations that contribute to the creation of value. At its heart, it boils down to compiling all of the information that is readily available within the organization and preparing it for the materiality assessment that will come next. All of the steps in the supply chain, including those that aren’t direct suppliers, are going to be displayed one after the other and supplemented with details on those phases’ activities and the companies that supply them.

Identifying important impacts on sustainability and deciding where to take action

The company can analyze and prioritize the risks to the environment and people based on the analysis and determination of sustainability elements and impacts. Stakeholders’ perspectives are critical to the collection of data on negative outcomes and risk mitigation. Taking a risk-based approach emphasizes that sustainable supply chain management should be addressed on a precautionary premise, and that the organization should seek to act preventatively.

Internal restructuring and process re-engineering

Materiality analysis and inventories are used to set up or modify new and current business processes inside the corporation. The organizational foundations for sustainable supply chain management must be laid as well, which include providing the necessary financial, human, and technical resources.

Defining and enforcing supplier requirements

The company creates a code of conduct throughout this stage of the process. It asks for a self-assessment of their implementation abilities and communicates requirements to direct suppliers. Conventional supplier evaluation is based on the results. A supplier’s code of conduct is included in the contract with the supplier, making it enforceable on both the primary and, if relevant, the secondary suppliers.

Most important advice: Create your companies frame work plan – way ahead before

Tactics, approach, blueprint, strategic plan – call it how you want, but create it. Forecast and simplify your operations as much as possible to make a plan. Then, as your plan is put into action, look for successful, repeatable parts that you can build out to make changes. In this way, when your supply chain gets out of whack again, you can keep getting better at adapting and responding.

In particular, forecasting is very important to setting shippers up for success. You need to spend the time to write a playbook for what will happen in your network when there is a disruption or seasonal event. Make sure you know about the unique seasonality, surges, and holiday schedule of your business and supply chain before you do anything. Re-examine these as often as possible and make changes to your plan based on the data and predictive analytics that are right for you.

Building supply chain resilience through digital transformation

In the wake of COVID-19, the supply chain was severely disrupted, necessitating the right-sizing of operations and the adoption of digital capabilities that protect supply chains from future disruptions. Investments in emerging technologies like blockchain, artificial intelligence (AI), machine learning and intelligent automation have proven to be the lifeblood of organizations across all industries. Take advantage of a digital marketplace for road freight like Saloodo! and maximize your sales and distribution strategy by taking advantage of the marketplaces’ capabilities in fulfillment, standardized delivery, rapid visibility, and compliance. The best part is that efforts to accelerate digital transformation will be rewarded by increased agility on the long run and less damages caught by a supply chain disruption in the future.